Can Sandblasting remove rust?

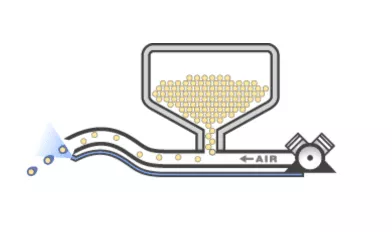

Yes, sandblasting can be used to remove rust; in fact, it is one of the best ways of clearing rust or corrosion from a metallic surface. Sandblasting is a common technique used in many metalworks industries and workshops to clean hard surfaces, roughen a smooth surface, shape a surface or remove surface contaminants. In this process, solid particles are forced across the hard surface at high speeds using compressed air. It is an efficient method for removing rust. Sandblasting breaks down the rust on the surface and reveals the clean metal underneath. Why is sandblasting better than other methods? There are quite a few methods available out there for removing rust, electrolysis, manual wire brushing, or bristle blasting but the problem with all these methods is that they are extremely time-consuming and labour intensive. These methods take tens of hours to remove rust and are only practical for smaller parts and in very limited quantitie...