Why use a Rust Inhibitor solution?

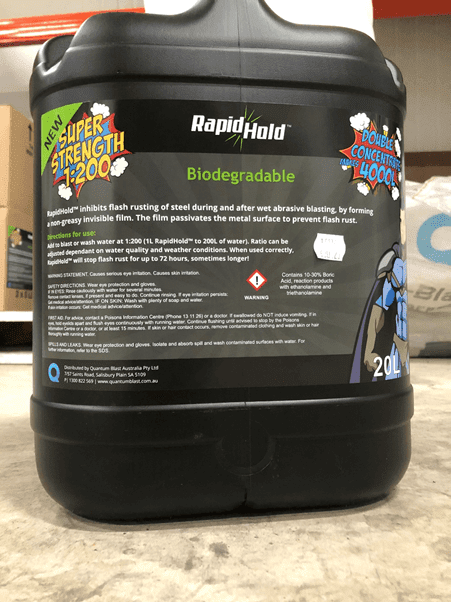

The use of a rust inhibitor solution such as RapidHold™ SuperStrength provides additional protection against flash rusting for upto 72 hours. The rust inhibitor can be added to the slurry mix of water and sandblasting media while blasted. For instance, the RapidBlast™ wet blasting machine also has an option for wash down whereby the surface can be rinsed off using the rust inhibitor solution mixed with water.

Flash rust is a general corrosion attack that presents a significant problem for abrasive blasters. Flash rust is problematic for dry blasting as well as wet blasting as blasting damages the passivating layer, which protects the metal from corrosion. In the case of vapour abrasive blasting, water is also present on the surface and in direct contact with the metal through the ruptured passivation layer. It is suitable for wet as well as dry abrasive blasting as well as acid bath rust removal. RapidHold™ SuperStrength is extremely economical to use as it is double the concentrate and requires half the quantity.

Comments

Post a Comment